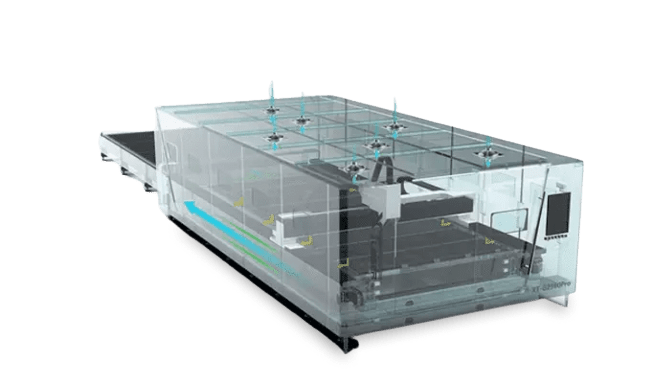

Solid machine with patented bed, 2G maximum acceleration and 180m/min cutting speed

ENDRESS ELT LASER research and development department consistently designs high-precision, vibration-free

Fast heat dissipation for a much longer lifetime

Coated with anti-burn plate to prevent heat deformation

Dust removal system

- Very good ventilation

- Push up and suction down

- Powerful ventilation system

- Left and right partition

Butterfly valve main control, concentrated suction, large diameter exhaust duct, fast smoke evacuation

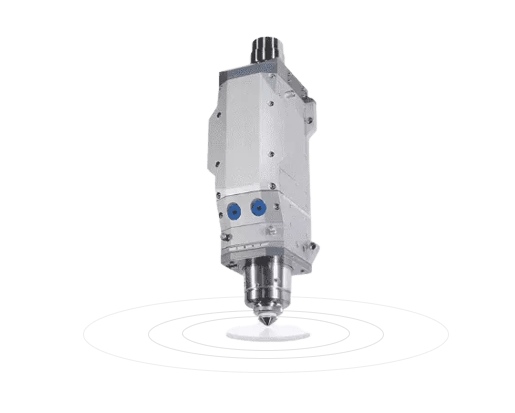

Autofocus laser cutting head

The software automatically adjusts the focus lens to make automatic punching and cutting plates of different thicknesses. Automatic focus lens adjustment speed is ten times faster than manual adjustment

CNC Bus System

Suitable for a high power fibre laser cutting machine over 8000W

It is widely used in sheet metal factories, automated production lines and large processing stations

Excellent improvement of high power cutting efficiency and stability

Convenient maintenance: provide operating data for focus testing and calibration, oscilloscope servo-monitoring and other products

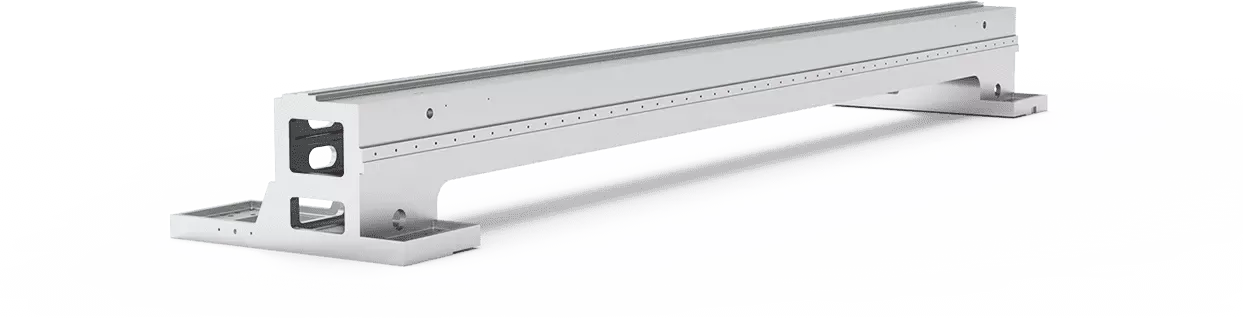

Cast aluminium beam

Reduced weight

Stronger

More sustainable

Imported / more accurate parts

Imported electrical parts

Schneider electrical parts ensure safe and efficient machine operation.

Germany brand gas valves

Cost savings through full use of gas

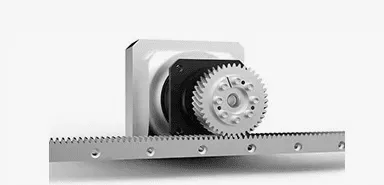

Imported transmission parts

Ensuring the accuracy of the equipment for a very long time

Imported / more accurate parts

Raytools Cutting Head

Raytools is not only the world’s largest manufacturer of dedicated laser machine components, but also the most reliable and technologically advanced.

In addition to low maintenance cost and long service life, the Raytools cutting head is a technology leader.

Thanks to the optimised automatic tracking algorithm, the laser head can avoid obstacles and achieve the best motor performance, while guaranteeing a stable cutting process and fast, precise movement.

The Z-axis reacts at high speed to avoid the detected obstacle, effectively preventing potential interference and laser head collision caused by part distortion during the cutting process on the thin plate surface.

Equipped with:

Precitec Cutting Head (OPTIONAL)

State-of-the-art technology meets innovation in a compact, high-performance design, giving you the perfect solution for your material processing projects.

High quality Fiber Laser sources

We work with the best and biggest in the industry and equip our machines with high quality fiber laser sources from the TOP 3 best manufacturers worldwide.

So our customers can choose the right source from Raycus, IPG or Reci according to their needs, wishes and budget.

Before the source is installed on the machine, we test it at full capacity on a special tester to make sure it is in optimal operating parameters and meets all the requirements the machine will need.

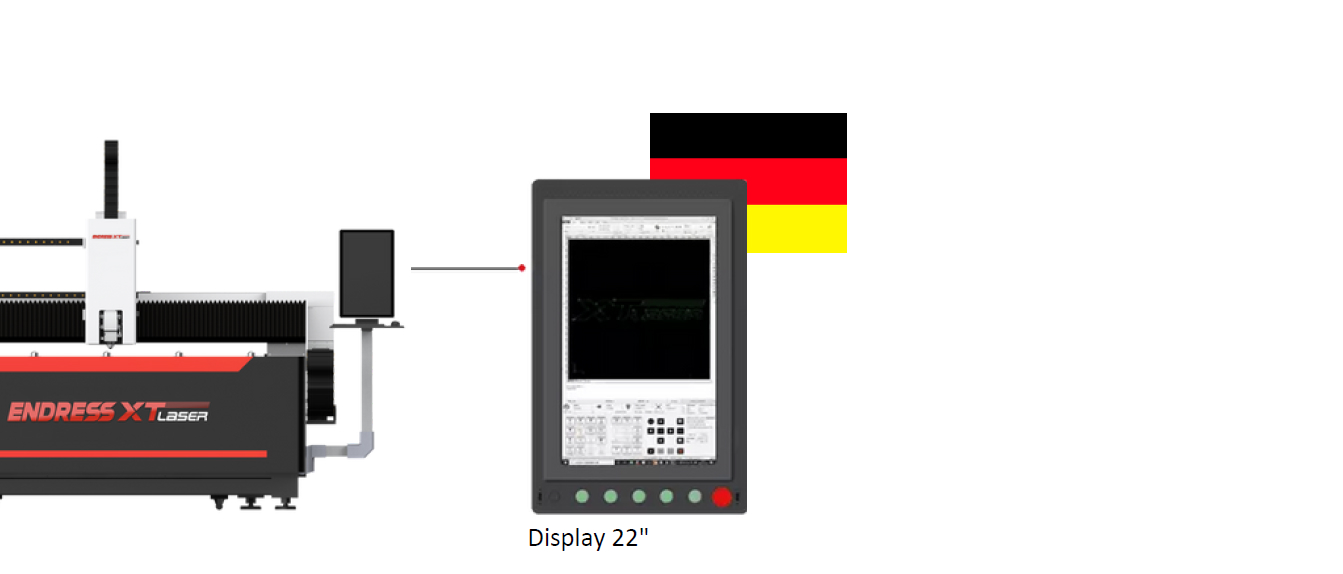

ELT Industrial Control Computer

Endress XT Laser machines are standard equipped with the ELT Industrial Control Computer – a state-of-the-art computer developed in Germany that helps both machine control and drawing storage and management, supporting any file format.

The computer allows quick diagnosis of the car, remote connection by a technician, file transfer both via internet and USB and data storage.

ELT High-Quality Cutting System

Standard Equipment

Developed in Germany and tested on dozens of materials and thousands of drawings, the ELT High-Quality Cutting System can handle any challenge.

It is a software system that optimises both the source and the laser head as well as the communication between the two to choose the best possible cutting quality depending on the thickness and type of material.

With this system, not only can any shape be cut to maximum quality, but the edges of the material will always remain smooth and free of imperfections.

Technical specifications

| Configuratie standard | Parametri tehnici |

|---|---|

| MAXIMUM SUPPORTED WEIGHT OF TIN SHEET | 7800 KG |

| TOTAL DIMENSION OF THE MACHINE | 18980*4090*2350 |

| WEIGHT OF THE MACHINE | 18480 Kg |

| POSITIONING ACCURACY IN REPEATED MODE | 0.02mm |

| TOTAL POWER/CURRENT OF THE ENTIRE MACHINE (WITH 8 KW LASER)OF THE MACHINE | 55KVA/85A |

| TOTAL POWER/CURRENT OF THE ENTIRE MACHINE (WITH 12 KW LASER) | 70KVA/110A |

| TOTAL POWER/CURRENT OF THE ENTIRE MACHINE (WITH 20 KW LASER) | 110KVA/160A |

| TOTAL POWER/CURRENT OF THE ENTIRE MACHINE (WITH 30 KW LASER) | 150KVA/225A |

| CHASSIS STRUCTURE | WELDED PLATES |

| STRUCTURE OF THE FASCULUM | ALUMINIUM |

| GUIDE RAIL | PEK FROM ITALY |

| AUTOMATIC LUBRICATION FUNCTION | YES |

| TABLE LOCKING FUNCTION | YES |

| SERVO MOTOR AND DRIVER | Fuji bus servo (X:1.3KW Y:2.9KW Z:0.75KW) |

| GEAR | Motoreducer From France |

| SWITCH | FRENCH SCHNEIDER |

| RELAY | FRENCH SCHNEIDER |

| ELECTRIC GAS PROPORTIONING VALVE | AVENTICS GERMANY |

| LASER HEAD | RAYTOOLS |

| LASER HEAD FOCUSING SYSTEM | AUTO-FOCUS RAYTOOLS |

| CONTROL SYSTEM | 12000W FSG6000-BLT44 ≥12000W FSG8000-BLT64 |

| NESTING SOFTWARE | OPTIONAL |

| LASER CUTTING PROCESS DATABASE | YES |

| COMPATIBLE FORMATS | G FILE, DXF, PLT, ENG G FILE |

| WATER COOLER | S&A OR HANLI |

| EXHAUST SYSTEM | EXHAUST WITH CENTRIFUGAL FAN. 11 KW |

| SECURITY SYSTEM | ALARM SYSTEM AND AUTOMATIC STOP |

| LASER HEAD ANTI-COLLISION SYSTEM | INCLUDED |

Included in the offer

| MODEL: ELT-GP2580 | LASER CUTTING MACHINE |

| WATER COOLER | STANDARD |

| COMPUTER CONTROL | STANDARD |

Optional equipment

| COMPATIBLE AIR COMPRESSOR |

| COMPATIBLE VOLTAGE STABILIZER |

| CYPNEST/TUBNEST NESTING SOFTWARE |

| PACKAGE CONSUMABLES |

Maximum cutting thicknesses depending on power and material type

|

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| 1000 | 1500 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Carbon steel | 12 | 14 | 18 | 22 | 25 | 30 | 35 | 40 | 45 | 80 |

| Stainless steel | 6 | 8 | 10 | 12 | 14 | 25 | 30 | 40 | 50 | 70 |

| Aluminium | 4 | 5 | 8 | 12 | 16 | 25 | 30 | 35 | 50 | 60 |

| Sign | 4 | 5 | 6 | 8 | 10 | 14 | 16 | 18 | 20 | 25 |

Timisoara

| Adress | Bvd. Ghioceilor nr 1, Dumbravita, jud. Timis |

| Phone: | 0760679519 |

| Fax: | (004) 031 817 66 08 |

| Email: | office@endress-group.ro |

Cluj-Napoca

| Adress | Calea Transilvaniei nr 14, Baciu, jud. Cluj |

| Phone: | 0760679519 |

| Fax: | (004) 031 817 66 08 |

| Email: | office@endress-group.ro |

Brasov

| Adress | Calea Feldioarei, Nr.106, Brasov |

| Phone: | 0760679519 |

| Fax: | (004) 025 522 78 28 |

| Email: | office@endress-group.ro |

Bucuresti

| Adress | Sos. Bucuresti nr 108, km 16 A1 – Ciorogarla |

| Phone: | 0760679519 |

| Fax: | (004) 255 227 828 |

| Email: | office@endress-group.ro |

Bocsa

| Adress | Str. Medresului nr 17, jud. Caras-Severin |

| Phone: | 0760679519 |

| Fax: | (004) 255 227 828 |

| Email: | office@endress-group.ro |

Iasi

| Adress | Valea Lupului, DN 28, nr. 118 |

| Phone: | 0760679519 |

| Fax: | (004) 255 227 828 |

| Email: | office@endress-group.ro |